The Endurance line absorbers are designed for a lifetime of at least 25 years.

This product is extremely robust with a very low attrition rate and can be easily regulated and refurbished like new, giving the shock absorber a multiple life.

The principle based on the oil circulation ensures a unique symmetric force and provides excellent heat transfer between the shock and the circulating air, allowing them to work in extreme conditions. Its design is optimized for the widest possible dependence while allowing more time between overhauls.

The Endurance line absorbers allow the following application:

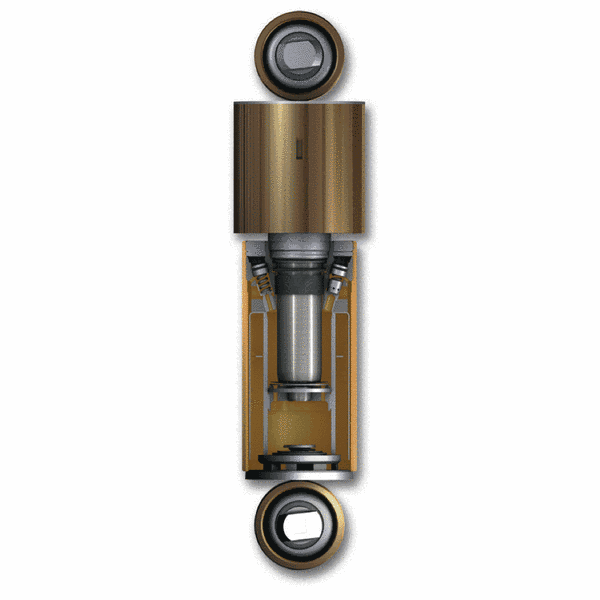

All absorbers from the Endurance Line operate on the principle of the circulating oil. This means that the oil is routed through the same system of valves in the guidance both during the compression stroke as the stroke length.

During the expansion stroke the check valve in the piston is closed and the oil is above the piston is pushed through the damping valve guide. At the same time, due to increased volume below the piston, the oil is directed through the bottom-return valve.

During the compression stroke bottom-return valve is closed and being pushed the piston down the cylinder, oil flowing through the check valve piston is now open. The oil displaced by the piston rod is pushed through the shock valving.

The robust construction of the Endurance line absorbers is reflected in:

After many years of trouble free service absorbers Endurance line can be repaired and regulated at the level of a new absorber again, thanks to its rugged construction. The damping forces can be regulated by acting on the adjustment screw with a screwdriver, so there is usually no need to remove the absorber or change internal components.